2.0ML Gumdrop Depositor Mold

Need specific volume pricing?

Email or call us at 714-202-6458

Need specific volume pricing?

Email or call us at 714-202-6458

Need specific volume pricing?

Email or call us at 714-202-6458

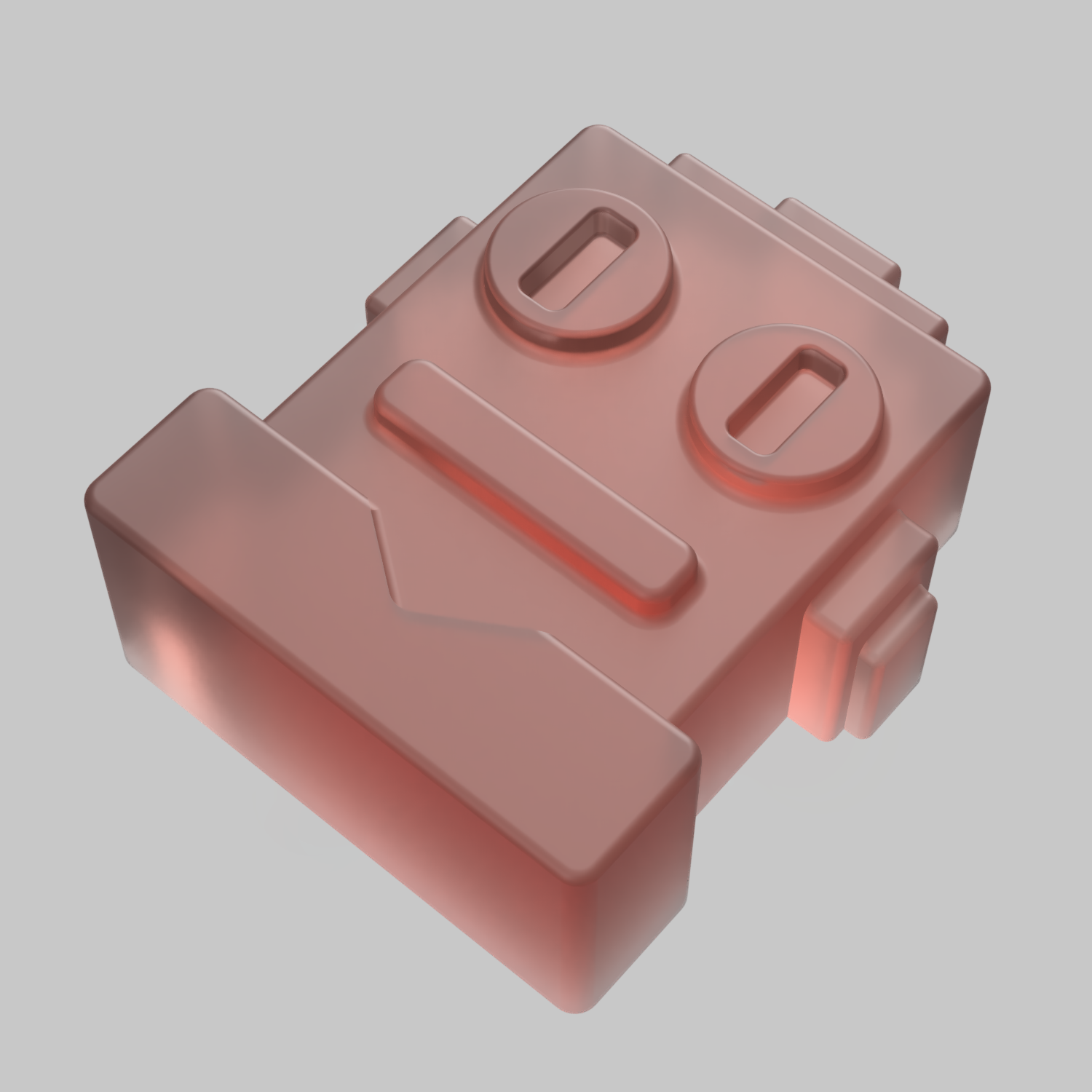

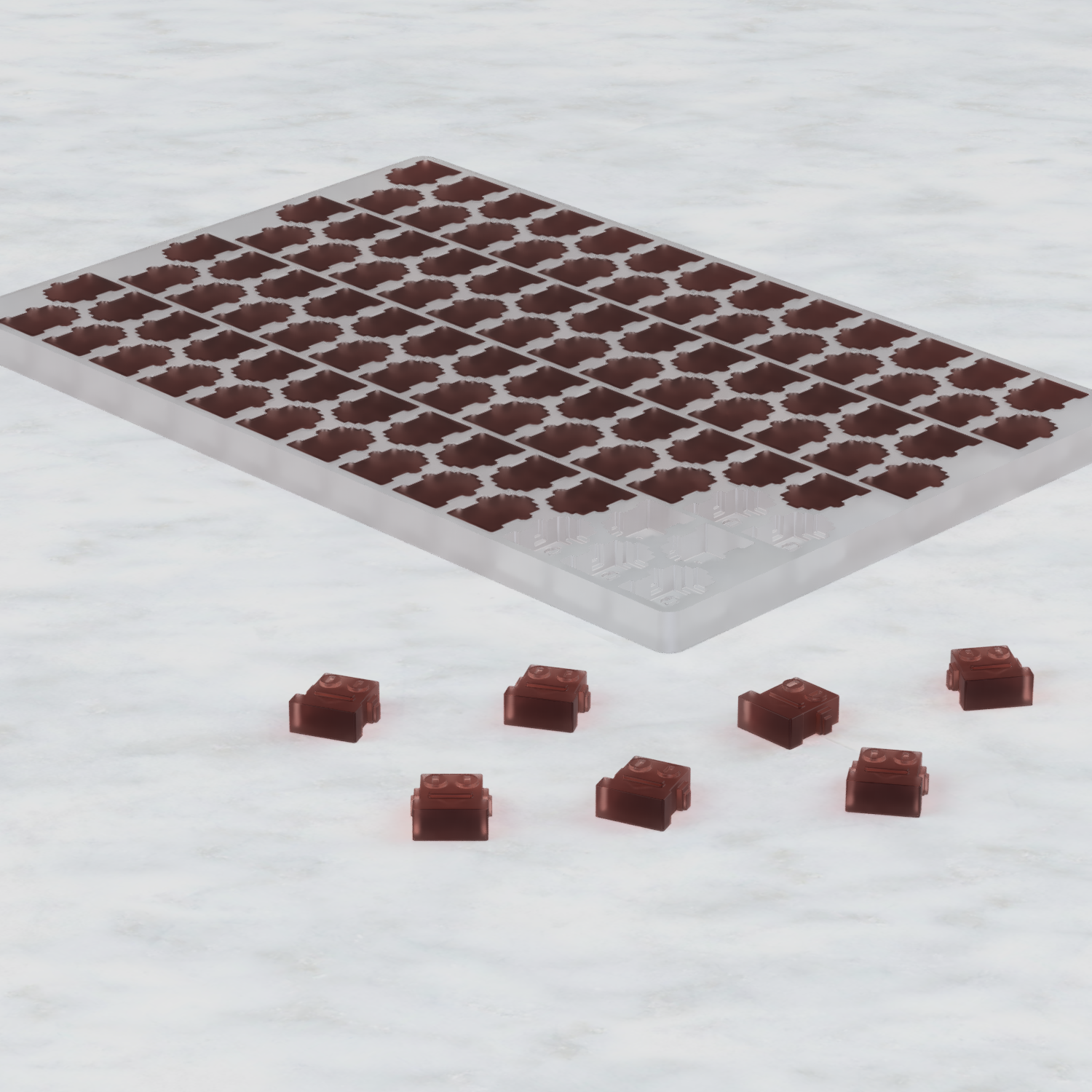

2.0 ML GUMDROP UNIVERSAL DEPOSITOR SILICONE CANDY MOLD UNIFY

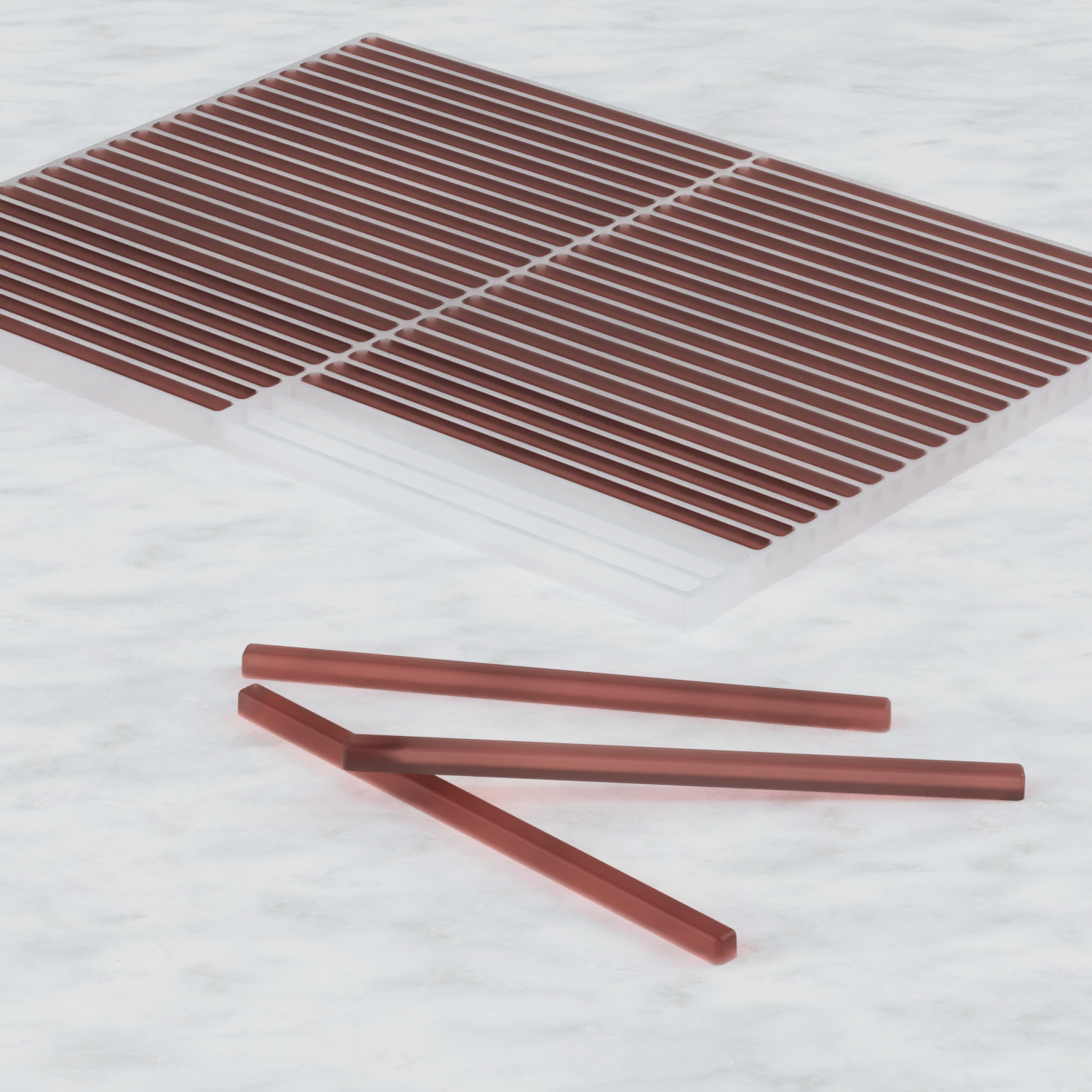

Goodie, goodie gumdrops are here! These 2 ML gumdrop molds are exceptionally easy to de-mold and offer an efficient use of space in a package that everyone loves. It uses FDA compliant silicone and will last 30 years, which means you'll never have to worry about your molds deteriorating or losing their shape.

This mold can be used for anything from gummies to hard candies to chocolate, making it perfect for both hand-pour and depositor methods. And it's made with temperature-safe silicone that can withstand up to 450 degrees F, so there's no need to worry about melting your creations!

It's specifically designed with a rapid demold rate so that you don't have to wait long before you can use your product—and since it works with all kinds of ingredients, there are no limits as far as what kind of creations you can make!

For those looking to purchase a large quantity of our products, we offer bulk discounts. We understand that larger orders can be more cost-effective for your business and we want you to get the best value for your money. Simply contact us at info@endosemolds.com, and one of our friendly team members will take care of you.

—

Key Features

100% FDA Compliant Food-Contact Safe Platinum Silicone

Temperature Resistant to up to 450 degree F

Proprietary Silicone Mix and Procedure To Ensure High-Quality

Manufactured With Latest Technology to Ensure Excellent Finish

Specifically Designed For Fast Demolding

Perfect For Gummies, Hard Candies And Chocolates

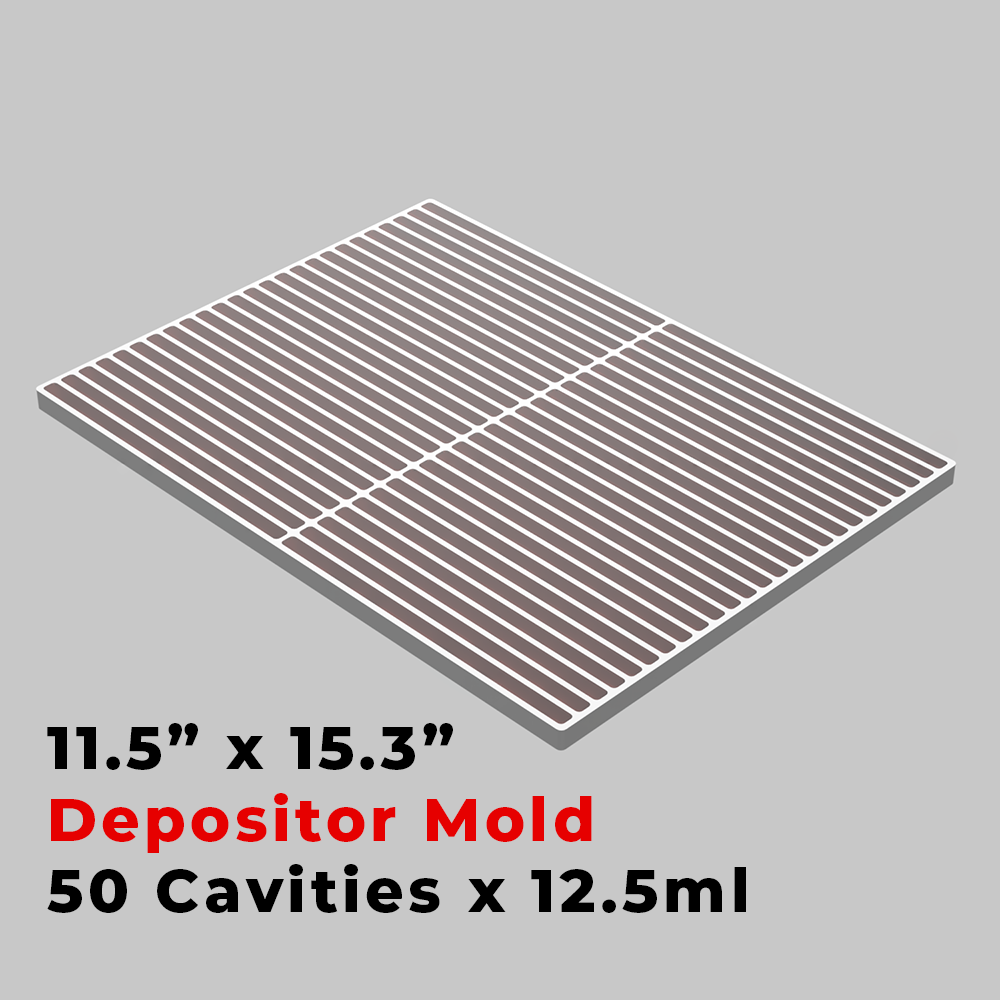

Specifications

Shape: Gumdrop

Compatible Methods: Hand-Pour and Depositor

Material: Silicone

Estimated Weight: 2.6 to 2.8 grams*

Cavity Dimensions (LxWxH): 17.5 mm x 17.5 mm x 10.5 mm

Cavity Volume: 2.0 ML

Number of cavities per mold: 266

Mold Dimensions: 11.5” x 15” (285 mm x 382 mm)

*End weight will be determined by the formula and SOP used. Variables which contribute to end weight include, but are not limited to, the primary type of gelling ingredient (i.e. pectin vs gelatin), coatings and length of dehydration.